ApplicationsWide application of heat-dissipating silicone using flat nozzle

- Industry

- Electrical Machinery

- Fluid

- High thermal conductive silicone grease (heat-dissipating silicone)

Current challenges and requests

To dissipate heat in the electric components, high thermal conductive silicone grease (heat-dissipating silicone) is used. The existing process involves applying silicone in lines and then spreading them out, but this method suffered poor precision. If the application volume is small, the required heat dissipation cannot be obtained, causing product failure.

The customer has no choice but to apply more than required, and as a result, high cost adhesives are wasted.

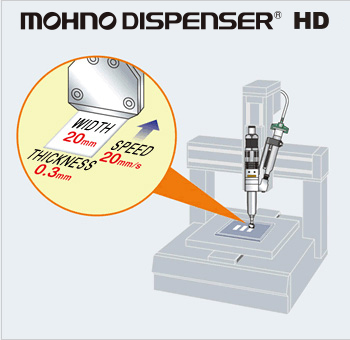

To make the component close contact with heat dissipating silicone, not line application but wide application is the first choice. However, using flat nozzle increases pressure loss. The existing equipment takes time to press the high-viscosity heat dissipating silicone out, causing to extend the cycle time.

Solutions and merit when improved

The Mohno Dispenser 3HD025G30 was introduced to handle high-viscosity heat dissipating silicone.

- The Mohno Dispenser's ability to discharge material instantly at high pressure allowed wide application using flat nozzle in a short time.

- Good fluid control with instantaneous reverse rotation at the completion of application provided consistent application shape.

- The basic principle of single-shaft eccentric screw with excellent metered performance provided consistent application volume, helping to reduce material loss and improve product quality.

Related information

-

Electrical Machinery

- Constant application of insulators in the motor production process

- Wide application of sealant to solar cell cover glass

- Line application of trace amounts of adhesives on resin case of electronic component

- Minute line application of high-viscosity adhesives on smartphone body

- High-precision dot application of solder paste without being affected by residual fluid fluctuation in a barrel (syringe)

- Stable mixing and high-precision application of two component hardening epoxy adhesives

- Food

-

Automotive

- Highly viscous thermally conductive material is applied to electric components

- Application of anti-seizure lubricant is automated

- High-precision dot application of high-viscosity heat-dissipating silicone on downsized electrical components for automotive

- Wide application of heat-dissipating silicone using flat nozzle

- Cosmetics

- Chemical, etc.