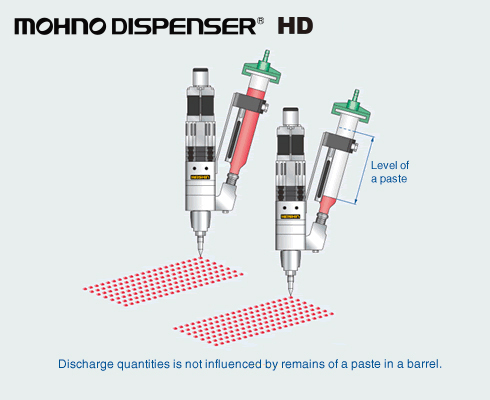

ApplicationsHigh-precision dot application of solder paste without being affected by residual fluid fluctuation in a barrel (syringe)

- Industry

- Electrical Machinery and Semiconductor

- Fluid

- Solder paste

Current challenges and requests

Solder paste is applied on the terminals of electronic substrates, however, the existing equipment has problems:

- Application volume increases as the residual paste in a barrel gets low.

- Case-by-case adjustment of application volume takes time.

- The customer wants to reduce high cost paste to be wasted as much as possible.

Solutions and merit when improved

The Mohno Dispenser 3HD010G30 was introduced to enable stable discharge without being affected by the fluctuation of the residual fluid in a barrel or the fluid viscosity.

- Unchanged application volume and stable dot application were provided due to the basic principle of single-shaft eccentric screw capable of metered discharge without being affected by the change of condition.

- Due to the drastic reduction of the frequency to change the operating conditions, wasteful tasks and loss of solder paste were significantly reduced.

- As application volume can be adjusted simply by adjusting the servomotor speed, the time to change the operating conditions was extremely reduced.

Related information

-

Electrical Machinery

- Constant application of insulators in the motor production process

- Wide application of sealant to solar cell cover glass

- Line application of trace amounts of adhesives on resin case of electronic component

- Minute line application of high-viscosity adhesives on smartphone body

- High-precision dot application of solder paste without being affected by residual fluid fluctuation in a barrel (syringe)

- Stable mixing and high-precision application of two component hardening epoxy adhesives

- Food

-

Automotive

- Highly viscous thermally conductive material is applied to electric components

- Application of anti-seizure lubricant is automated

- High-precision dot application of high-viscosity heat-dissipating silicone on downsized electrical components for automotive

- Wide application of heat-dissipating silicone using flat nozzle

- Cosmetics

- Chemical, etc.