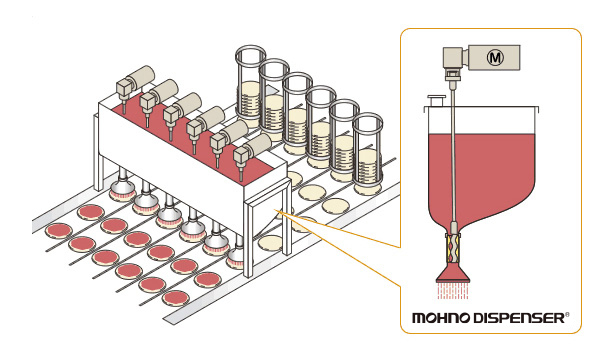

ApplicationsSerial application of pizza sauce to pizza bases with good fluid control

- Industry

- Food

- Fluid

- Pizza sauce

Current challenges and requests

The existing equipment had poor fluid control, which was causing pizza sauce to drip from nozzles even after application.

While the dripping slowed naturally over time, it did not stop completely. As the production line was forced to operate in such a state, the drips splattered over the surrounding area-production lines had to be stopped for cleaning numerous times a day, which prevented production from being completed as per the schedule.

Sauce was also wasted. These issues had to be resolved without a major modification to the existing production line.

Solutions and merit when improved

Mohno Dispenser NVDL, which features good fluid control, was designed and custom-made to fit into the existing production line.

- The reverse motion after finishing application instantaneously cuts fluid flow. This saves waiting time and accelerates production speed.

- Since there is no dripping, surrounding areas remain clean, eliminating the need for clean up work.

- Yield is improved as sauce is no longer lost due to dripping.

Related information

-

Electrical Machinery

- Constant application of insulators in the motor production process

- Wide application of sealant to solar cell cover glass

- Line application of trace amounts of adhesives on resin case of electronic component

- Minute line application of high-viscosity adhesives on smartphone body

- High-precision dot application of solder paste without being affected by residual fluid fluctuation in a barrel (syringe)

- Stable mixing and high-precision application of two component hardening epoxy adhesives

- Food

-

Automotive

- Highly viscous thermally conductive material is applied to electric components

- Application of anti-seizure lubricant is automated

- High-precision dot application of high-viscosity heat-dissipating silicone on downsized electrical components for automotive

- Wide application of heat-dissipating silicone using flat nozzle

- Application of a pumpable sound deadener inside vehicle pillars during the body manufacturing process

- High-speed application of a high-viscosity, high-damping mastic sealer with sufficient thickness

- Cosmetics

- Chemical, etc.