ApplicationsMinute line application of high-viscosity adhesives on smartphone body

- Industry

- Electrical machinery

- Fluid

- Adhesive

Current challenges and requests

In applying adhesive on smartphone body, the customer was required to apply minute beads of less than φ1.0mm. However, as the viscosity of adhesive is high, installing a thin needle with the existing equipment requires longer application time due to pressure loss.

Additionally, due to inconsistent application lines, the customer has no choice but to frequently adjust the application volume. This takes much time, thus resulting in loss. In applying two-part adhesives, the mixing ratio of a base component and a hardener cannot be kept consistent and such adhesives cannot be cured properly.

Solutions and merit when improved

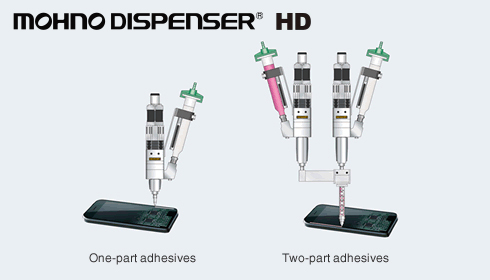

The Mohno Dispenser 3HD025G30 was introduced to handle high-viscosity material of 1000000 mPa·s.

- Can be discharged instantly even with a thin needle, helping to reduce the application time significantly.

- The discharge volume can be easily adjusted simply by changing the rotational speed of the servomotor, thus helping to reduce setup time and material losses.

- The proportions of the compounds are easy to adjust because the amount of base compound and the amount of hardener dispensed can be easily changed. Accurate mixing and applying provided stable quality.

Related information

-

Electrical Machinery

- Constant application of insulators in the motor production process

- Wide application of sealant to solar cell cover glass

- Line application of trace amounts of adhesives on resin case of electronic component

- Minute line application of high-viscosity adhesives on smartphone body

- High-precision dot application of solder paste without being affected by residual fluid fluctuation in a barrel (syringe)

- Stable mixing and high-precision application of two component hardening epoxy adhesives

- Food

-

Automotive

- Highly viscous thermally conductive material is applied to electric components

- Application of anti-seizure lubricant is automated

- High-precision dot application of high-viscosity heat-dissipating silicone on downsized electrical components for automotive

- Wide application of heat-dissipating silicone using flat nozzle

- Application of a pumpable sound deadener inside vehicle pillars during the body manufacturing process

- High-speed application of a high-viscosity, high-damping mastic sealer with sufficient thickness

- Cosmetics

- Chemical, etc.