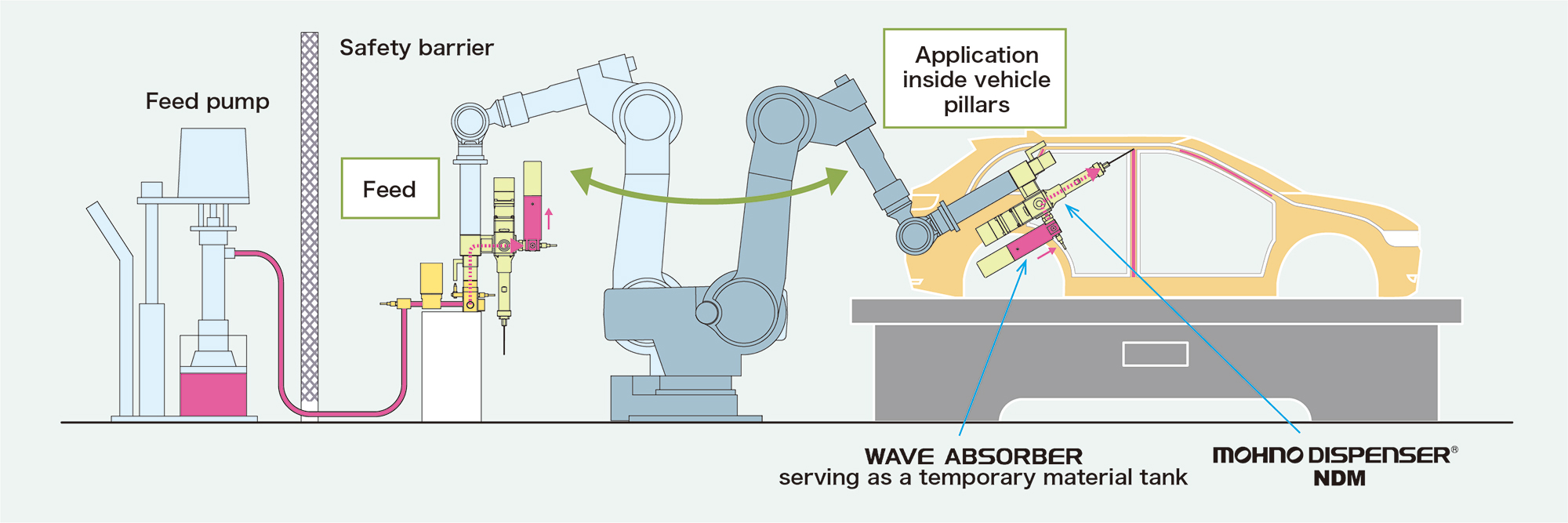

ApplicationsApplication of a pumpable sound deadener inside vehicle pillars during the body manufacturing process

- Industry

- Automotive

- Fluid

- Pumpable sound deadener

Current challenges and requests

In the body manufacturing process, a sheet-type sound deadener was applied manually. However, applying the deadener in hard-to-reach areas increased operator workload and posed a risk of missed installation. Switching to a liquid material promised reduced backing-paper waste, but introducing a pumpable sound deadener presented several challenges.

- The pumpable sound deadener had to be applied deep inside pillar structures.

- The ultra-high-viscosity material had to be applied quickly, with sufficient width and thickness to ensure effective sound deadening.

Solutions and merit when improved

To address these challenges, the Hose-Free System—capable of high-precision application of highly viscous materials—was adopted.

- With no hoses on the robot’s moving parts, the Hose-Free System enabled flexible application even in deeply recessed areas of the vehicle body.

- Eliminating hose constraints also simplified robot teaching during setup.

- Even with ultra-high-viscosity material approaching 1,000,000 mPa·s, the Hose-Free System consistently applied the required amount with high accuracy and within the specified cycle time.

- Switching to a pumpable sound deadener enabled process automation, reducing manual labor while ensuring high sound insulation performance.

Related information

-

Electrical Machinery

- Constant application of insulators in the motor production process

- Wide application of sealant to solar cell cover glass

- Line application of trace amounts of adhesives on resin case of electronic component

- Minute line application of high-viscosity adhesives on smartphone body

- High-precision dot application of solder paste without being affected by residual fluid fluctuation in a barrel (syringe)

- Stable mixing and high-precision application of two component hardening epoxy adhesives

- Food

-

Automotive

- Highly viscous thermally conductive material is applied to electric components

- Application of anti-seizure lubricant is automated

- High-precision dot application of high-viscosity heat-dissipating silicone on downsized electrical components for automotive

- Wide application of heat-dissipating silicone using flat nozzle

- Application of a pumpable sound deadener inside vehicle pillars during the body manufacturing process

- High-speed application of a high-viscosity, high-damping mastic sealer with sufficient thickness

- Cosmetics

- Chemical, etc.